Producing circuit loads up is a procedure that requires significant investment and is not viewed as a “straightforward thing” to do. In spite of the fact that, there are fans that can make their own sheets at home with the right materials, yet they normally have a tendency to be not as mind boggling as machine made ones. Likewise, it would be pretty tedious to hand make 20,000 PCBs. Underneath, I will quickly walk you through the PCB Assembly handle and what is included at every stage.

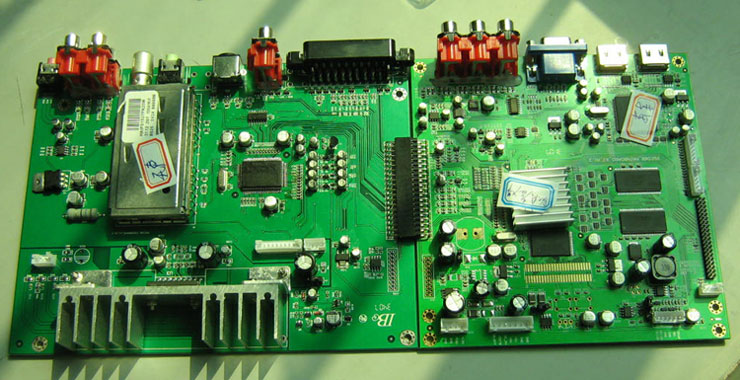

Assembly, which is otherwise called Printed Circuit Board Assembly, is the point at which you bind electronic parts to a PCB or printed circuit board. A circuit board that has not yet been gathered with the electronic segments are called PCB or Printed Circuit board and once the sheets have fastened segments on them, they are in fact alluded to as Printed Circuit Assembly or Printed Circuit Board Assembly.

Remember that circuit board get together is not as a matter of course the same as circuit board fabricating. When you make PCBs, it includes various procedures that incorporate PCB Design and really making the linked model. The sort of segments and the procedure of the get together rely on upon the kind of circuit board it is, somewhat electronic segments that should be associated, and what electronic gadget the board will be added to.

In this way, after it is done being made, it is the ideal opportunity for the different electronic parts to be connected to it with the end goal it should really be utilitarian. This is here and there alluded to as PCBA or Printed Circuit Board Assembly. There are two sorts of development strategies utilized for the get together.

1) Through-Hole development: Component leads are embedded into the openings

2) Surface-Mount development: Components are set on terrains or cushions on the external surfaces of it.

Notwithstanding, in both development sorts, the part leads are still electrically and mechanically settled to it with liquid metal bind.

Contingent upon the volume of sheets that should be gathered will decide how the segments will be bound. On the off chance that it is for a high creation volume, then binding parts to the Printed Circuit Board is best done by machine arrangement. Machine position is finished with mass wave patching or reflow stoves. Something else, if the generation amount is for little volume models, fastening by hand works fine and dandy as a rule (Ball Grid Arrays are really difficult to bind by hand).

Frequently, through-opening and surface-mount development must be performed in one PCB get together in light of the fact that some required electronic segments just accessible in through-gap bundles, while others are just accessible in surface-mount bundles. Additionally, it is a justifiable reason motivation to utilize both of the techniques amid the same gathering in light of the fact that through-opening mounting can really give more quality to the electronic parts that are liable to experience some physical anxiety.