Ensuring that the pulleys in your belt-driven systems are properly aligned is critical for maintaining the longevity and efficiency of your machinery. Misalignment can lead to increased wear and tear, energy loss, and even equipment failure. Here are five essential tips for achieving optimal alignment with a pulley alignment tool.

Understand the Basics of Pulley Alignment

Pulleys must be parallel and level with each other to minimize belt wear and ensure efficient power transmission. Understanding the common signs of misalignment, such as uneven belt wear or unusual noise, is also vital. This foundational knowledge makes the process much smoother when using devices designed to aid in alignment.

Prepare Your Equipment and Workspace

Ensure that the machinery is safely powered down and locked out before attempting any adjustments. Clean the pulleys and belts to remove any debris that might skew your measurements. Preparing your equipment involves inspecting the pulleys for wear or damage, as these conditions could affect alignment accuracy and overall system performance.

Choose the Right Tool for Your Application

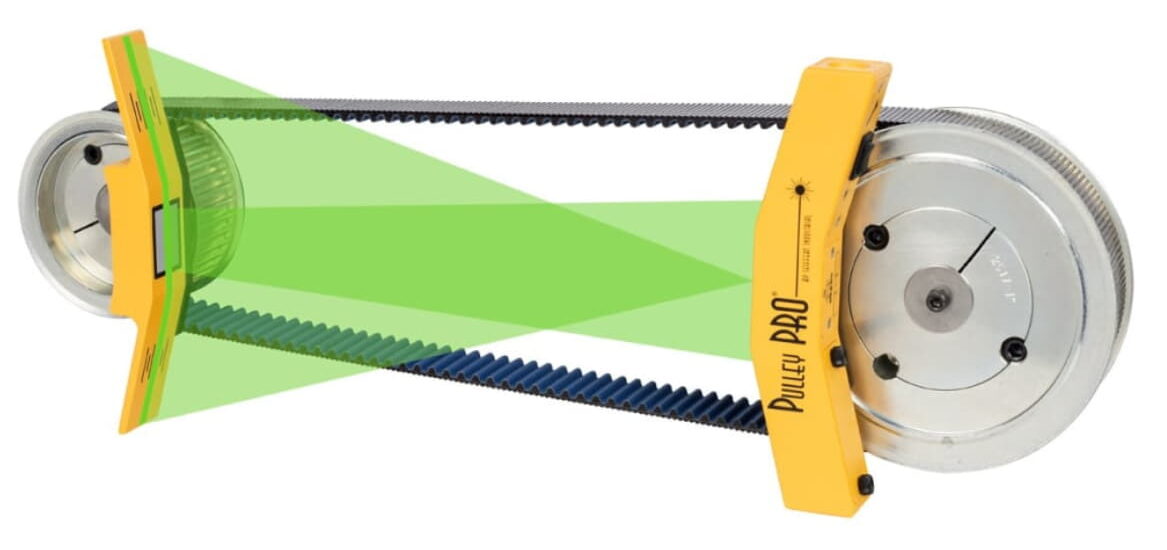

While there are various methods and tools available, opting for one that suits your machinery’s specific needs and your comfort level is important. Devices that use laser technology offer high precision and can significantly simplify the alignment process. However, understanding the capabilities and limitations of your chosen tool is key to its effective application.

Follow a Systematic Alignment Process

Alignment is not just about making adjustments; it’s about doing so systematically. Start by aligning the pulleys at the closest point of approach, which is typically where the belts leave the pulleys. From there, ensure that the faces of the pulleys are parallel. Using your alignment device according to the manufacturer’s instructions can help you achieve precise alignment efficiently.

Regularly Monitor and Maintain Alignment

Proper pulley alignment is not a one-time task but an ongoing part of maintenance. Regularly inspect your belt-driven systems for signs of misalignment and wear. Implement a scheduled maintenance plan that includes alignment checks using your preferred alignment device. This proactive approach can help prevent unplanned downtime and extend the life of your equipment.

By following these tips and using a pulley alignment tool effectively, you can ensure that your belt-driven systems operate smoothly, efficiently, and with reduced risk of premature failure. Remember, the key to successful pulley alignment lies in understanding the basics, preparing thoroughly, choosing the right tool, following a systematic process, and maintaining a commitment to regular monitoring and maintenance.