Pulley alignment is the process of setting the pulleys in a belt or chain drive so that they are collinear with each other. The benefits of alignment include reduced vibration, reduced noise, increased belt life, and increased efficiency.

It is a critical part of any belt or chain drive system. Incorrectly aligned pulleys can cause vibration and noise and can lead to premature failure of the belt or chain.

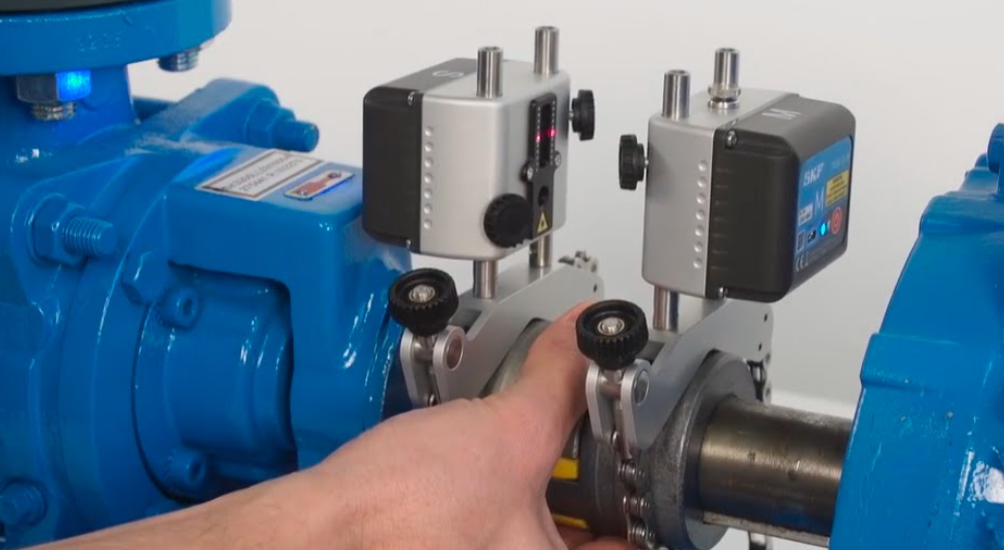

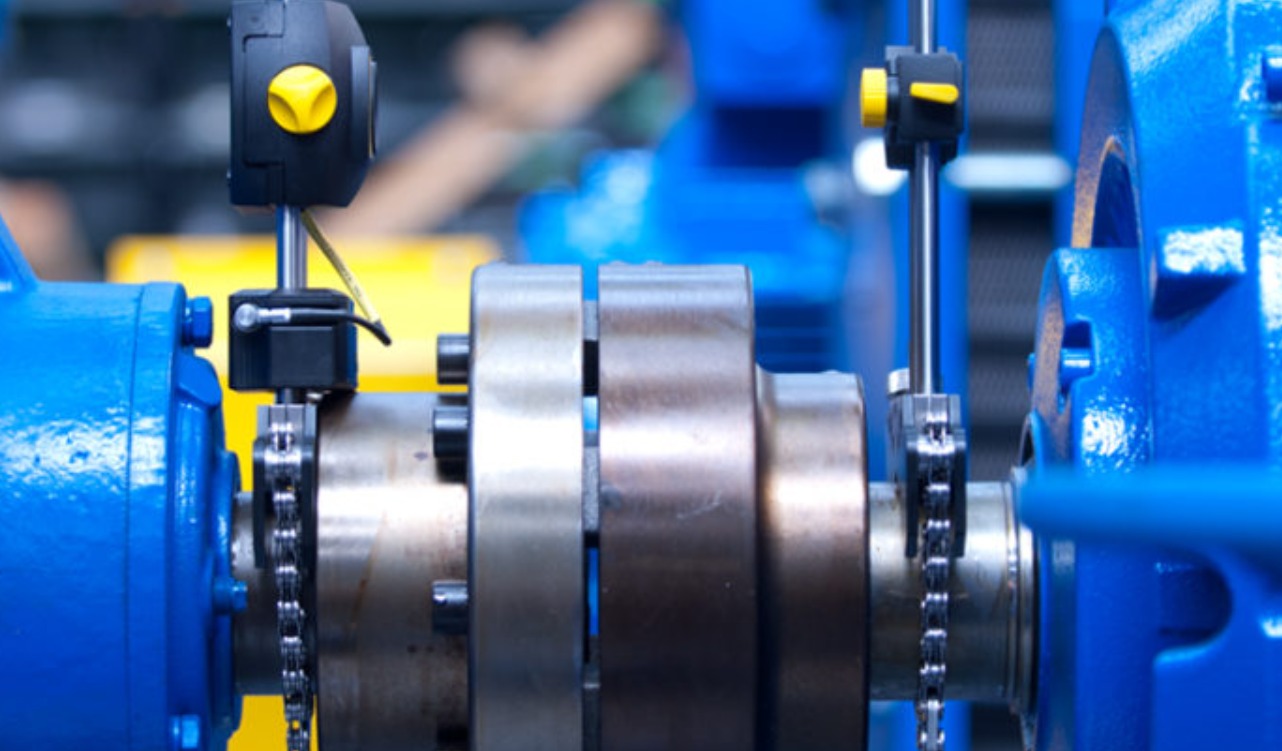

It is typically done using a laser alignment system. This system uses lasers to align the pulleys so that they are collinear with each other. The laser alignment system also measures the angular misalignment between the two pulleys.

It is a simple yet critical process that should be done regularly to ensure the proper operation of the belt or chain drive system.

Reduced vibration

Reduced vibration is one of the most important benefits of pulley laser alignment. Vibration is a major source of noise, which can irritate people and damage sensitive equipment. Pulley misalignment will cause additional friction in the belt or chain drive system, which increases vibration. The pulleys must be aligned, so they are parallel to each other and perpendicular to the direction of travel.

Reduced noise

Reduced noise is one of the most important benefits of alignment. Vibration is a major source of noise, which can irritate people and damage sensitive equipment. Pulley misalignment will cause additional friction in the belt or chain drive system, which increases vibration. The pulleys must be aligned, so they are parallel to each other and perpendicular to the direction of travel as like pump alignment tool.

Increased belt or chain life

It is an important part of any belt or chain drive system because it reduces wear on belts and chains. When pulleys are not aligned properly, they can rub against each other instead of running smoothly on their shafts. This causes premature wear on belts or chains because they have to work harder to overcome this friction

Reduced maintenance costs.

Misaligned pulleys can also lead to increased maintenance costs because they’re more likely to break or wear out prematurely due to excess strain on the components. This can cause costly breakdowns and preventable downtime for your machinery (and employees).

Increased efficiency.

When your pulley alignment is off, your belt will be stressed, which means it’ll wear faster and perform worse over time. This increases friction and reduces power output, so you’ll end up wasting energy on wasted motion instead of focusing on moving your product forward.

Related Sources: Belt Alignment Tool, Belt Sheave Laser Alignment Tool