Misalignment of the pump alignment tools may lead to equipment faults, accidents, and injuries. There are too many opportunities for error when relying on human judgment; hence tools are needed to place shafts.

The pump laser alignment tools, for instance, may ensure faultless coupling and tolerances far below the acceptable margin.

The machine alignment laser is based on laser technology, which is not a new concept but has been improved to become very reliable and precise. Using a gyroscope-based approach to align couplings is the sole alternate option. Although they are less costly, they lack the precision of laser systems and are difficult to set up, making them unsuitable for situations requiring rapid responses.

Some Unique Benefits Of Pump Alignment Tools

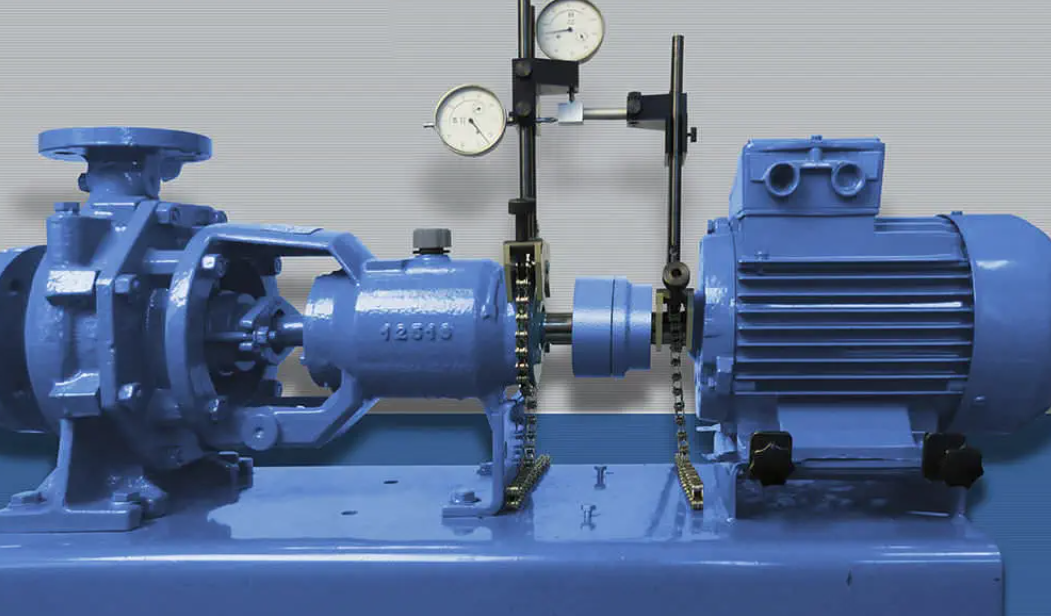

There are two forms of misalignment that may occur between components: angular and parallel. The lines are angularly misaligned, whether they are on the same plane or a distinct plane. The shafts’ lines are parallel but misaligned vertically or horizontally. Regardless of the kind of misalignment that exists, pump alignment tools and equipment may correct it.

Using laser leveling equipment, an example may be produced to demonstrate how the technology can provide such precision. The laser generates an absolutely straight line with minor deviations. Using laser technology, machine alignment lasers may achieve the same precision within a few hundred millimeters.

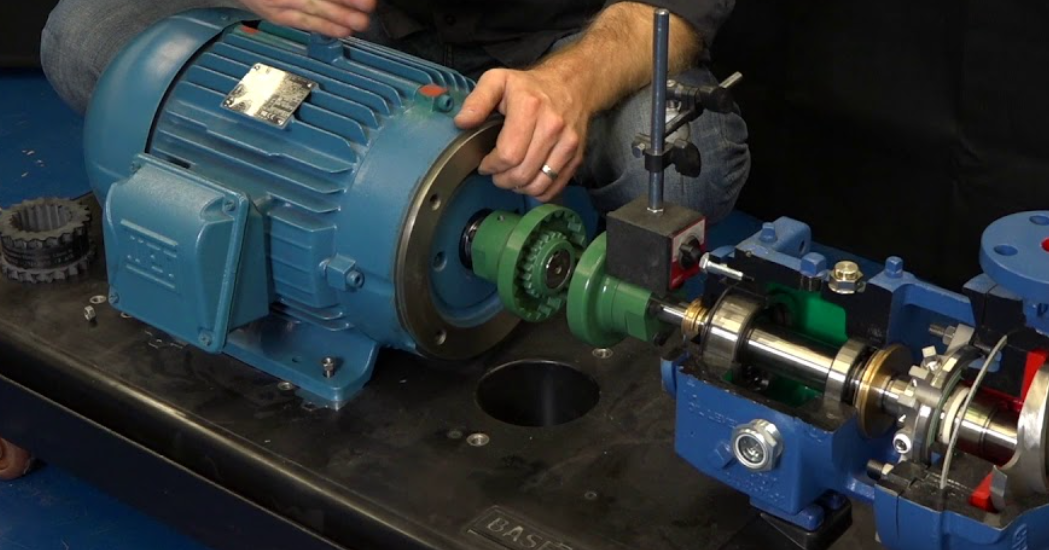

The equipment’s three primary components are the laser, the sensor, and the electrical gadget. When the laser shoots a light beam to the sensor, an electronic device receives the data and displays the required adjustments. Due to the precision of the data, remedial interventions may be customized to the same constraints.

This approach is used on equipment and components such as turbines, compressors, gearboxes, couplings, generators, and propeller shafts. It is used by gas and oil industries, construction, paper & pulp, pharmaceutical, and wastewater management sectors.

Not only can pump laser alignment equipment expedite the replacement of components, but they also save money. Reduced labor costs, reduced installation time, and a speedy installation are the benefits of a labor-saving system. All of these factors will result in a less costly alignment method. Consider how the technology will help plants as part of their alignment management approach.

On couplings, generators, turbines, and compressors, pump alignment tools equipment, which comprises a laser, a sensor, and an electronic device that calculates measurements, may be used. For more information visit our Website.